Roofing Shingles

Roofing Shingles are the most commonly used roofing material in North America, which are now being widely preferred across India.

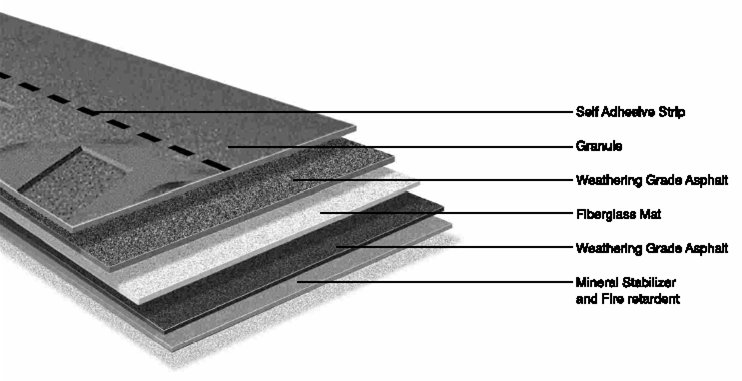

Shingles come in the form of 3 feet x1 feet sized sheets, in a thickness range of 4 to 12 mm. They are composites of reinforced fiberglass mesh and mineral stabilized, high grade asphalt, which has been overlaid with high strength ceramic coated granules.

They can be conveniently applied on any kind of sloped roofs -RCC slab/wood/fiber cement board etc.

Please scroll down for detailed Product Description, Advantages, Available Designs and Patterns and Application Procedures.

Product Description

Our Roofing shingles are Fiberglass reinforced, high grade, Mineral- stabilized asphalt based mats which are overlaid with high strength ceramic coated granules and underlayed with a mineral stabilizer cum fire-retardant

General pattern is made up of two pieces of shingles which are laminated together to form a thicker product to enhance its aesthetics and dimensional appeal. A more varied blend drop effect and shadow line is usually added to make it more aesthetically pleasing.

- CONSTRUCTION- Double laminates fiberglass composition: UL Class A

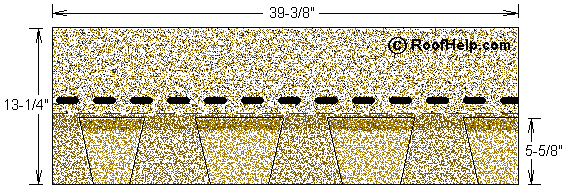

- SIZE – 335 mm X 1000 mm

- EXPOSURE – 145 mm

- WARRANTY – 25 years limited warranty (see warranty for specific details & limitations)

- WIND RESISTANCE – 15 years 100 km/hr. as per ASTM D3161

- FIRE RATING – Class A fire rating as per ASTM E108/ UL S107-M87

- SPECIAL FEATURE- Self adhesive strip

Advantages of Shingles

Key Advantages

- Aesthetic

- Waterproof

- Unbreakable

- Zero maintenance

- Algae resistance

- Warranty

Description of Benefits

- Very durable, in comparison with other alternative roofing products.

- Light in weight – Hence easy to handle.

- Flexible – Aids easy installation.

- Zero Water Absorption

- Availability of Wide range of colours and variety of patterns.

- Can be folded at hips and ridges. Need not be pre-cut.

- Wind resistant, impact proof, fire proof and can withstand – 40 to +100 degree centigrate temperature

- Can be applied even on very steep slopes ranging from 15 to 90 degrees.

- Overlap of more than 50%. This ensures complete waterproofing.

- Versatility of the product. Can be applied both on wooden and concrete decks.

- Comply with ASTM D 3462 for tear resistance (1700 Grams minimum)

- Confirm to ASTM E108 , Class A fire resistance

- Certified by Underwriters Laboratories Inc.

Application Procedures

Application Procedure – For Concrete Decks

- All concrete surfaces shall be overlaid with a minimum of 1” Cement screed

- Surface provided shall be duly rendered to a smooth finish and bone dry.

- A coat of bituminous primer will be applied and left till it touch- dry.

- All junctions (if any) of sloping roof with a vertical wall or valley gutter if any will be lined with one feet wide flashing membrane

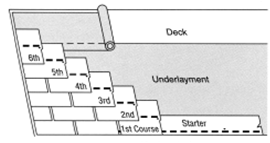

- Starter course will be fixed at the bottom of sloping roof surface (Eave edge) before commencing the application of Roof shingles.

- Roof shingles will then be fastened using approved Corrosion resistant nails, at suitable distance as per manufacturer’s specifications.

- The front part of the shingle shall be stuck to the subsequent shingle using the self-adhesive tape provided at the bottom.

- Ridges will be fixed once the surface coverage is complete

Application Procedure – On Structures with Fiber Cement Board or Wooden Decks

- The Fiber cement Board or wooden deck (Marine–Ply) should be minimum of 16 mm thick (Should not warp in presence of moisture).

- The gaps between Boards to be kept zero and flashed using self-adhesive membrane.

- All junctions if any of sloping roof with a vertical wall or valley gutter if any will be lined with one feet wide flashing membrane

- Starter course will be fixed at the bottom of sloping roof surface (Eave edge) before commencing the application of Roof shingles.

- Roof shingles will then be fastened using approved Corrosion resistant Screws / Nails

- The front part of the shingle shall be stuck to the subsequent shingle using the self-adhesive tape provided at the bottom.

- Ridges will be fixed once the surface coverage is complete

For Application on substrates other than Concrete and wooden decks, contact us